|

Written By: John Macrae & Helana Robbins Huddleston CohnReznick In today’s challenging economic environment, manufacturers face significant pressure to reduce operational costs while also improving performance by increasing revenue and EBITDA to achieve an overall improvement in equity value. In this article, we will explore some of the ways manufacturers can use performance improvement initiatives to increase a company’s overall earnings and equity value using key data derived from the CohnReznick Manufacturing Checkup Survey that asked 172 U.S. manufacturing executives to assess the efficiency and effectiveness of corporate functions critical to profitable performance of their business. The survey included a diverse set of industrial firms, both private and public. Don’t underestimate the power of financial modeling Financial models are a structured representation of your business strategy and they are often the first step towards performance improvement. The goal of modeling is to accurately project a manufacturer’s future financial performance based on the impact of various strategic and operational decisions. They are used inside and outside the manufacturer to improve decision-making and forecasting around variable and fixed costs absorption, inventory costing and management, gross margin dilution, capital allocation, strategic investments, and cash management including fundraising. Utilize sales and operations planning to optimize your business Sales and operations planning (S&OP) is another key process that can help improve business operations. S&OP is a management process used to develop a unified plan for meeting customer demand by aligning sales, marketing, finance, and operations processes and teams. It includes demand planning, procurement and supply planning, inventory management, and production planning. The goal is to help ensure the manufacturer’s primary assets, people, materials, and equipment are effectively utilized to meet customer demand while minimizing cost and maximizing profitability, cash flow, and ultimately enterprise value. According to the CohnReznick Manufacturing Checkup Survey, one-fifth of manufacturers report challenges with enterprise planning and forecasting. To implement S&OP, management should try to ensure inputs and outputs align across sales forecasts, production plans, and financial budgets. It also requires an increase in communication and alignment across sales, marketing, finance, and operational departments to enable data-driven decision-making among the key stakeholders. Once completed, the S&OP, along with the financial model, should allow management to better balance supply and demand across product lines. Hone-in on key performance indicators Another critical step to improve operations is to establish key performance indicators (KPIs). The best KPIs are leading metrics that provide early warnings of problems that may harm your bottom line. KPIs can also lead management to focus in on areas for continuous improvement. Common KPIs used by businesses include:

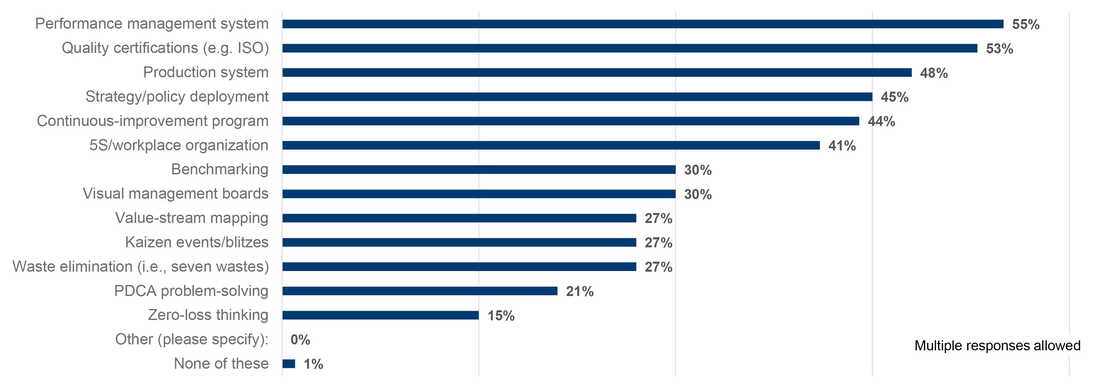

Make continuous improvement part of your culture Continuous improvement is a common term that many managers want to achieve but are not sure how to do it. First, it should be thought of as the manufacturer’s culture and philosophy, not a project. It seeks to improve every process in your business by focusing on enhancing the activities that generate the most value for your customer while removing as many wasteful activities as possible. In the CohnReznick Manufacturing Checkup survey, we found that (Figure 1):

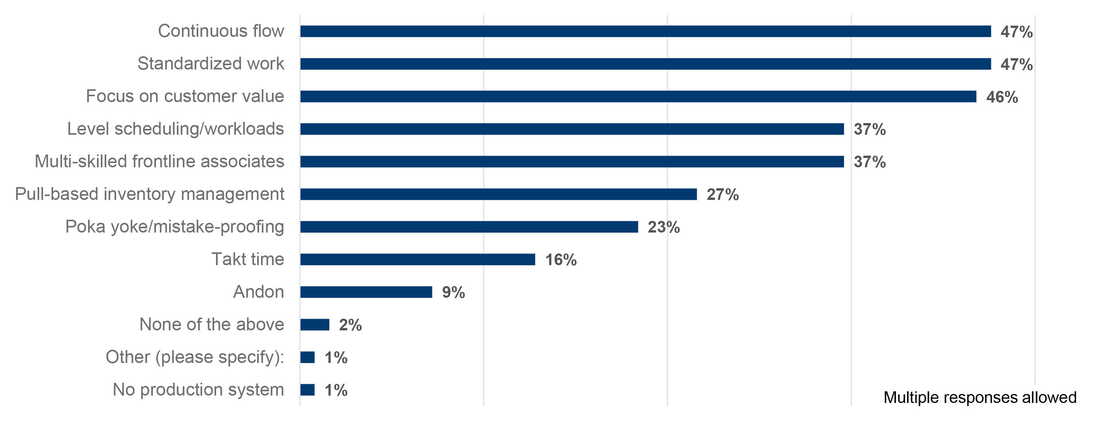

Figure 1 There are several different methods that are used to achieve continuous improvement programs including Lean and Six Sigma. A business has the opportunity to expand capacity through reorganization of plant equipment and/or production schedules to increase equipment optimization and efficiencies. As a manufacturer considers ways to implement continuous improvement into daily operations, the use of technology should also be considered. Technology can automate processes, reduce errors, improve quality, and enhance communication among various departments. Lean-based production The CohnReznick Manufacturing Checkup Survey also highlighted that approximately half of the manufacturers surveyed utilize lean-based production principals (Figure 2) which indicates a large opportunity for improved efficiencies that can immediately impact your bottom line. Lean-based production principals can help to boost innovation, cut costs, eliminate waste, and optimize production processes. FIGURE 2. LEAN-BASED PRODUCTION PRINCIPLES USED TO INCREASE EFFICIENCIES AND DRIVE VALUE FOR CUSTOMERS (% OF MANUFACTURERS) Figure 2

Examples of lean-based production principles include:

Skilled and motivated workforce A stable, engaged, educated, and empowered workforce is another prominent driver of success that can help to increase efficiencies and reduce costs. By investing in training and development, employees are more likely to increase productivity, reduce errors, and improve quality. Additionally, by educating and empowering employees to speak up, a manufacturer can experience enhanced innovation from the employees mastering the production process. The use of technology is also an important factor here. The use of technology helps make a manufacturer’s workplace more desirable. This, in turn, helps attract and retain employees, especially younger workers who are more familiar and comfortable with technology. Manufacturers may need to invest in talent, and pay more competitive wages and benefits, but any increased costs are offset by lower employee turnover, and less usage of unskilled and/or temporary labor to meet customer demand. Conclusion Manufacturers have ample opportunities to improve their operations, earnings, and equity value in this current market, and often it takes an outside perspective with a fresh set of eyes to identify potential areas of opportunity. CohnReznick has assisted many manufacturing clients implement best practices and performance improvement programs to help reduce costs and increase equity value. Let us help you too.

0 Comments

Leave a Reply. |

Guest Blog

Archives

July 2024

Categories |

- About Us

- Events & Programs

-

Forums

- Diversity, Equity & Inclusion Forum

- Environmental Business Council

- Family-Owned Business Forum

- Healthcare Foum

- Higher Education Forum

- Human Resources Forum

- International Forum

- Manufacturing Forum

- Marketing Forum

- Next Gen: A Young Professionals Organization

- Non-Profit Forum

- Real Property Forum

- Technology for Business Forum

- Transportation Forum

- Women in Commerce Forum

- Membership

- COMMERCE Magazine

- Member Directory

- Member News

- Guest Blog

|

Copyright Commerce and Industry Association of New Jersey. All Rights Reserved.

365 West Passaic Street Suite 490 | Rochelle Park, NJ 07662 Phone: (201) 368-2100| [email protected] | sitemap |

RSS Feed

RSS Feed